Bever IIIA

1. Information

The Bever IIIA is a decentralised biological wastewater treatment system with capacities varying from 22 up to 500 p.e. A perfect application for food, industry, communities, holyday/caravan parcs.

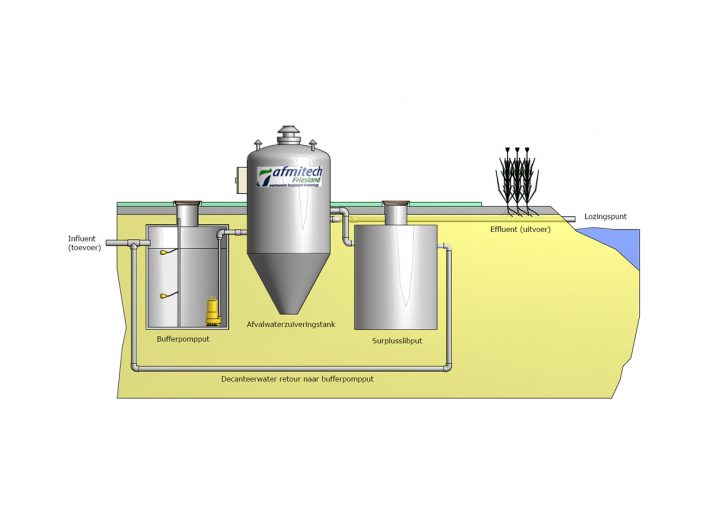

The innovative compact design allows to place the system in different situations. The system consist of only three main parts: a lightweight, reinforced polyester process tank, a sludge thickener and a settling tank. As a result the system is suitable for area’s with a limited space. Therfore is it also a good solution for industrial area’s, since digging is not always desirable due to the existing infrastructure. The Bever IIIA is suitable to treat industrial wastewater as well as communal wastewater. Even a combination of sources is possible to treat. Especially relevant to metnion is that the quality of the effluent allows re-use for process or irrigation water.

Application examples for the Bever IIIA:

- dairy farms

- housing and office clusters

- small communities

- camping and caravan sites

- restaurants and hotels

- breweries

- fruit juice producers

- meat industrie

Advantages of the Bever IIIA

System:

- No additional pretreatment with chemicals is necessary

- Very compact system using less than 50% of space for similar, fully biological WWTP’s

- Small systems are fully covered and bigger systems can easily be covered, thus:

- Reducing smell and noise

- Giving very good and stable performance during extreme winter conditions

- All process equipment prefabricated, leading to reduced construction and installation time

- Additional treatment steps, at own choice, can easily be installed and applied for sludge (drying, biogas) or effluent polishing (re-use of effluent water )

Process technolog:

- Automatic sludge thickening and discharge

- Specially designed frequency controlled surface aerators, set automatically at variable intervals adjusted to the BOD/COD load

- Fully automated treatment process

- State-of- the-art communication technology, enabling remote control setting and adjusting of process parameters (sludge, aeration and flow)

- Easy adjustment for seasonal variations of load (as option)

Treatment efficiency:

- COD (Chemical Oxygen Demand) 94.9 %

- BOD 5 (Biological Oxygen Demand) 99 %

- Total Nitrogen > 85.5 %

- Biological Phosphate removal > 50 %

- Suspended Solid 99.3 %

- NH 4 -N 98.7 %